PMD Capabilities

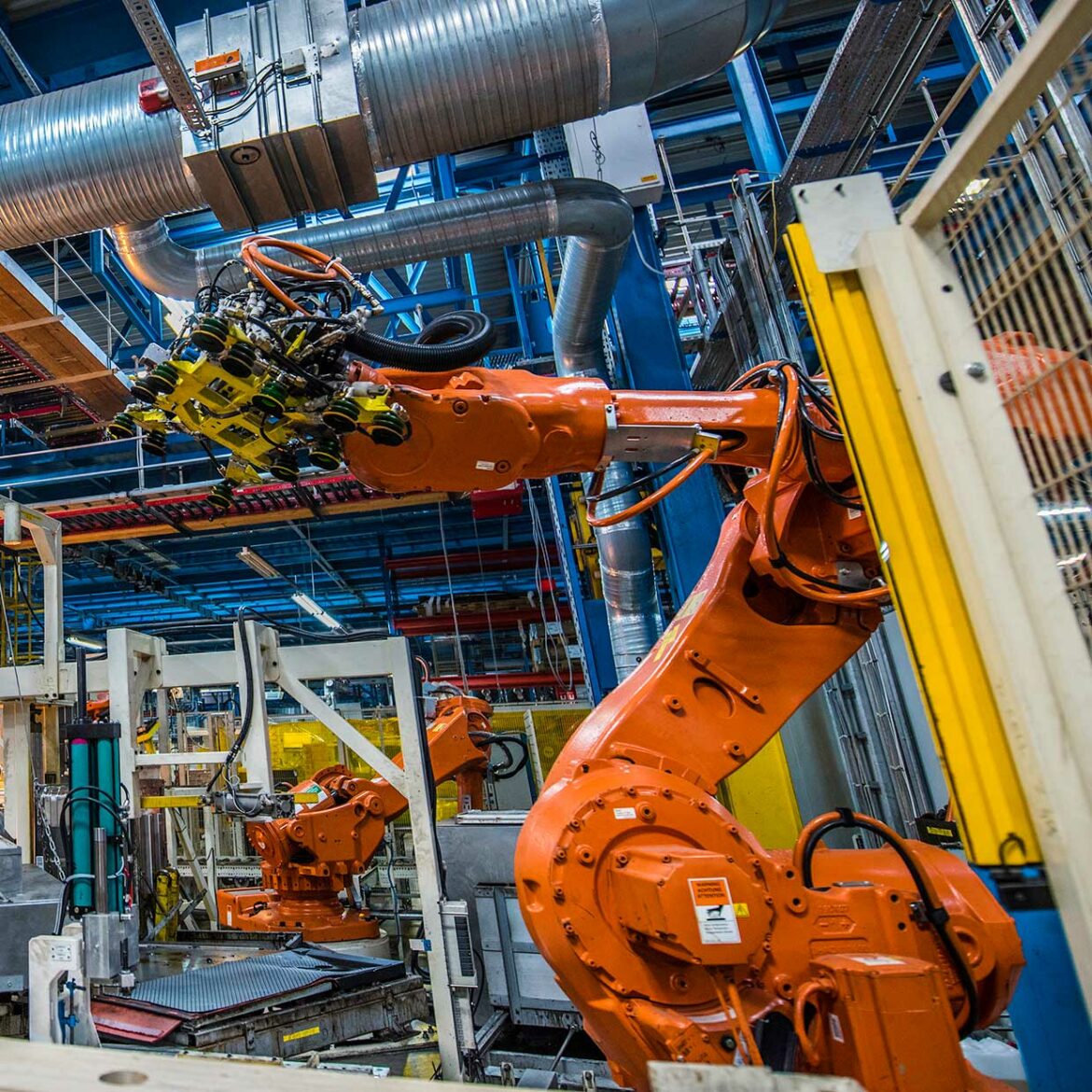

MATERIAL HANDLING

Automated Material Handling Systems (AMHS) from PMD help you make the most efficient use of your human labor force, speed up the assembly process, reduce workplace accidents, and improve productivity. The AMHS uses RFID, barcodes, and other tracking systems to pinpoint the location of any part or component and move it to the right place at the right time.

PMD has the knowledge and expertise to design and build your AMHS, provide installation assistance, and provide systems integration as well so that your automated material handling system communicates clearly with your manufacturing execution system (MES) and your Enterprise Resource Planning (ERP) system.

Material Handling

Areas of Expertise

- Discreet, Bulk, and Liquids

- Palletizing, packaging, cartoning

- High Speed Synchronous / Asynchronous

- Precision Link Chassis

- ICT – Independent Cart Technology

- Part Feeding Specialists

- AMR – Automated Mobile Robots

Material Handling

Synchronous/ Asynchronous

With synchronous manufacturing, production utilizes a transfer line to move material to different production stations. All parts move together from place to place.

By contrast, asynchronous process manufacturing (APM) the transfer line allows greater flexibility, allowing parts to move independently when a process is complete.

An automated material handling system is designed to handle both situations with ease, even at high speeds.

Material Handling

Part Feeding – Tray, Bulk & Flex Feeding

Our automated tray handling systems load or unload trays of parts and track them throughout the automated system, so there is never a “missing” part or component.

Our bulk material handling systems are suitable for bulk filling as well as bulk unloading.

A flex feed system takes bulk fed components and uses vision-guided robotics and conveyor systems to execute machine pick-and-place functions with speed and accuracy.

Material Handling

Dispensing

Accurate volumetric control of fluids as well as path control – these are critical parameters in the automated dispensing industry and part of the skill set of the PMD engineering group. Understanding flow characteristics of a variety of materials with differing viscosities and having the experience to apply the right components are critical to a successful dispensing system. In markets from semiconductors to batteries, glass to medical devices, PMD has provided innovative solutions that have helped clients gain an edge.

Material Handling

Packaging & Palletizing

As inventory or supply streams have become more customized to reduce costs the value of very flexible unit builds has justified the use of robotics.

Material Handling

Web Handling

A web is generally processed by moving over rollers and through a variety of stations until all operations on the product are complete. The motivation to work with webs instead of sheets is normally economics in that webs are continuous, can be made at far higher speeds, and do not have the start-stop issues of discrete sheet processing. The benefits of web handling include maximizing productivity and minimizing waste.

Material Handling

Independent Cart Technology

Independent Cart Technology (ICT), also known as Smart Conveyors, is the latest solution for motion control challenges, providing flexibility and performance enhancements. Intelligent Conveyor Technology gives machine designers the opportunity to design a ‘pitchless’ machine that can be easily adjusted to your specific application.

- Flexibility Revolutionized!

- Independent product/pallet control

- Reduced floor space

- Increased throughput

- Decreased changeover

- Extreme Reliability – Reduced Downtime

- Enhanced Safety Zones

- True ‘Pitch-less’ design

PMD

CAPABILITIES

High Precision Apps

Some applications require high precision beyond what standard technology offers. PMD has experience in high-precision applications with tolerance requirements in the 0.1 µm range.

Laser

Lasers are used in many different applications in automation. From marking to ablation to welding, cutting, and more. PMD can run process experiments with our in-house laser as well as specify and integrate lasers of all manufacturers, types, and applications.

Contract Manufacturing

We can take your products and idea from prototyping through production to packaging across all materials. Full design for manufacturing engineering support is available to develop cost-effective precision machining solutions to support Kan-Ban/JIT sourcing of your precision machined parts.

Filling

Filling systems are a staple in the life sciences and healthcare industry. PMD designs high-volume filling lines to handle a wide variety of bottle shapes and sizes while controlling dispensed volume and/or weight.