PMD Capabilities

MACHINE VISION

Advancements in camera, optics, and processing technology continue to expand the scope of applications for vision in automation. PMD has made it a priority to employ the brightest vision professionals in order to provide the highest level of solutions to our clients.

Machine Vision

Areas of Expertise

- Automatic ID

- Metrology

- Surface Defects

- Feasibility Lab

- 3D Inspection & Scanning

- Expert Application Evaluation

- Robot Flex Feeding / Guidance

- Ultra High Resolution

Machine Vision Applications

Quality Inspection

Have a large model matrix? Machine Vision can be used to provide high-speed inspection of many aspects of your products. Whether it’s a pallet full of parts traveling down a conveyor or a single part feeding down a track, machine vision can provide a 100% inspection of your products.

Machine Vision Applications

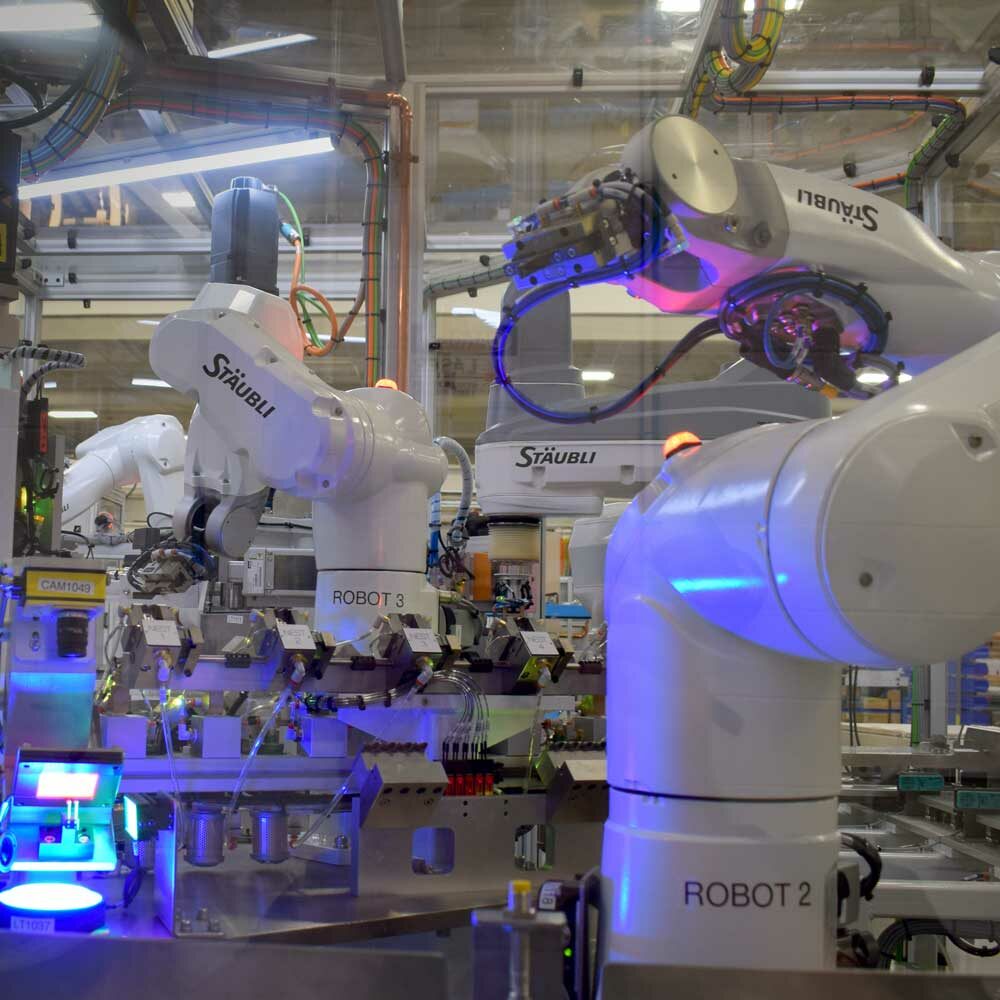

Robot Guidance

Machine vision is also essential for robot guidance. Robot guidance can be related to scene as well as objects. For scene guidance, a camera that’s mounted on the robot transmits images for mapping and object identification. Mapping would guide a robot from one end of the production floor to the other for instance, allowing it to maneuver around any obstacles.

Object-related machine vision is more common in assembly verification and quality inspection, where the camera would be mounted to obtain a close-up view of the object(s) in question.

Machine Vision Applications

Model Recognition

Model Recognition, object detection and recognition, and pattern recognition are all important parts of machine vision. By programming more data or identifying variables into your machine vision software, you increase the machine vision system’s accuracy.

Machine Vision Applications

Defect or Fault Detection

Machine vision improves production control and eliminates human error. Thanks to the rapid image processing, defective parts are identified quickly. If machine vision detects a defect or fault, it will sort the part or product out and away from the rest of the items being inspected. By removing flawed parts from the assembly process immediately, you prevent them from being used in the finished product.

Machine Vision Applications

3D Vision Inspection

3D visual inspection goes above and beyond 1D bar code recognition or optical character recognition (OCR). 3D sensors look at length, width, and height. 3D machine vision captures images using laser triangulation and high-resolution, real-time measurements. 3D vision inspection is ideal for parts inspection and identification, volumetric measurements, and bin-picking applications.

Machine Vision Applications

Flex Feeding

Machine vision improves production control and eliminates human error. Thanks to rapid image processing, defective parts are identified quickly. If machine vision detects a defect or fault, it will sort the part or product out and away from the rest of the items being inspected. By removing flawed parts from the assembly process immediately, you prevent them from being used in the finished product.

PMD

CAPABILITIES

High Precision

Some applications require high precision beyond what standard technology offers. PMD has experience in high-precision applications with tolerance requirements in the 0.1 µm range.

Laser

Lasers are used in many different applications in automation. From marking to ablation to welding, cutting, and more. PMD can run process experiments with our in-house laser as well as specify and integrate lasers of all manufacturers, types, and applications.

Contract Manufacturing

We can take your products and idea from prototyping through production to packaging across all materials. Full design for manufacturing engineering support is available to develop cost-effective precision machining solutions to support Kan-Ban/JIT sourcing of your precision machined parts.

Filling

Filling systems are a staple in the life sciences and healthcare industry. PMD designs high-volume filling lines to handle a wide variety of bottle shapes and sizes while controlling dispensed volume and/or weight.