PMD Capabilities

ASSEMBLY SYSTEMS

Assembly automation is the foundation of PMD’s business. In creating world-class automated assembly systems, the integrator must have expertise in motion platforms, machine vision, robotics, joining technologies, material handling, DFM, part traceability, and a variety of other automation tools. Our partners and clients rely on PMD Engineering for the ability to efficiently integrate all of these while keeping in mind program yield, commercial, and time to market goals.

We use an integrated engineering process with daily brainstorming sessions to conceptualize bullet-proof automated solutions and mitigate risk.

Assembly Systems

Areas of Expertise

- High-Speed Assembly

- Transport Platforms

- Part Feeding

- Robotic Assembly

- Joining Technologies

- Sub-Micron / High-Precision

- Material Handling

- Part Traceability

- Integrated Assembly Systems

- Inspection Systems

- Packaging

- Fluidized Dispensing

Assembly System Applications

Robotic Assembly

During the past several years the use of robotic systems is very common in the automation of product assembly processes. PMD has configured many assembly cells in a broad range of capability and cost. New and developing sensory systems both within and external to a robotic platform have allowed a great deal more sophistication in moves required of a robot.

Assembly System Applications

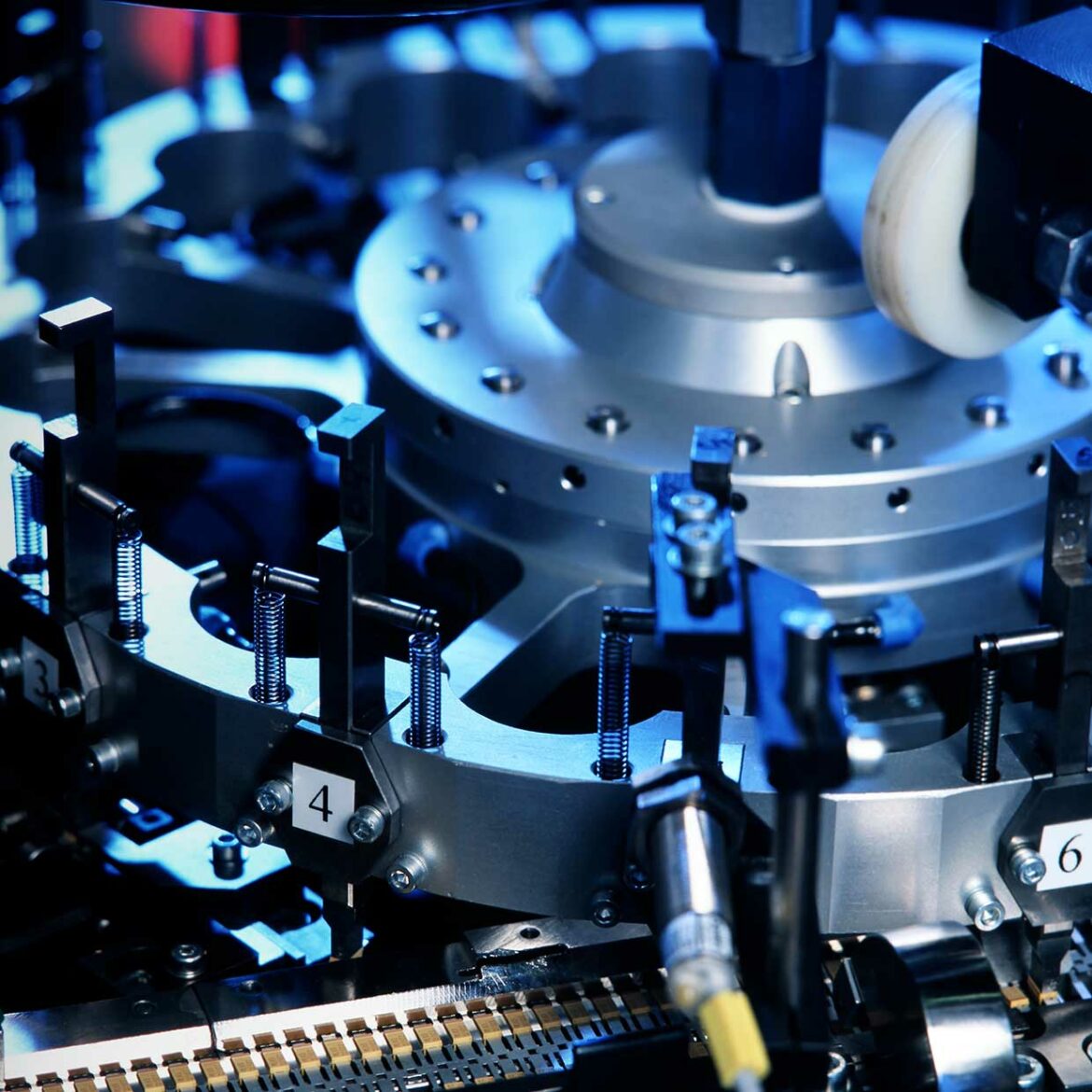

Rotary Machines

Rotary assembly machines, or rotary dial indexing assembly cells, offer efficiency, rapid indexing, rapid deployment, and lower cost. Most consist of a servo indexing central dial or ring indexer which is both fast and very accurate. Most system stations are fed by vibratory feed systems or pick and place robotics. Station tooling is fixed in place and provides precise and repeatable operations for high-quality results. Completed components/assemblies can be automatically unloaded to finished containers or conveyors for further processing.

PMD has extensive experience designing and building multi-station rotary dial machines for clients in a variety of industries.

Assembly System Applications

Cam-Driven Motion Platforms

The most significant benefit of a mechanical cam system is speed. Some of the fastest automation solutions are cam-based due to the exacting control of movements within a mechanism. Tooling motion follows a precise and predictable path which allows for high speed with acceleration dynamics that favor a smooth, quiet running system.

Assembly System Applications

Controlled Environments

Our global experience with a variety of products, clients, geographic requirements, and environmental challenges have given PMD a huge bank of expertise. This saves you time, cost, and risk because we have already done it!

- Pharma & Medical Clean Rooms

- Modular Clean Rooms

- Aseptic Manufacturing

- Certification & Installation

- Explosive and Classified Environments

Assembly System Applications

Web Handling

A web is generally processed by moving over rollers and through a variety of stations until all operations on the product are complete. The motivation to work with webs instead of sheets is normally economics in that webs are continuous, can be made at far higher speeds and do not have the start-stop issues of discrete sheet processing. The benefits of web handling include maximizing productivity and minimizing waste.

Assembly System Applications

High Precision Processing & Assembly

PMD harnesses the power of our 75+ strong engineering group to concept robust and reliable solutions to your most demanding applications.

- Sub-Micron Expertise

- Proof-of-Concept in the PMD Lab

- Experience w/Nanometer Stages & Hexapods

- Utilization of advanced Vision

- Characterization analysis

Assembly System Applications

Lean Cells

Working with your Engineers, PMD can create effective solutions to address the production issues that arise in today’s JIT production environment. Our solutions address bottleneck constraints, optimize capacity fluctuations, ergonomic concerns, process additions, capital downsizing, and floor space utilization. This can all be done quickly through lean cell implementation without the need for intensive capital investment and long lead times.

PMD

CAPABILITIES

High Precision

Some applications require high precision beyond what standard technology offers. PMD has experience in high-precision applications with tolerance requirements in the 0.1 µm range.

Laser

Lasers are used in many different applications in automation. From marking to ablation to welding, cutting, and more. PMD can run process experiments with our in-house laser as well as specify and integrate lasers of all manufacturers, types, and applications.

Contract Manufacturing

We can take your products and idea from prototyping through production to packaging across all materials. Full design for manufacturing engineering support is available to develop cost-effective precision machining solutions to support Kan-Ban/JIT sourcing of your precision machined parts.

Filling

Filling systems are a staple in the life sciences and healthcare industry. PMD designs high-volume filling lines to handle a wide variety of bottle shapes and sizes while controlling dispensed volume and/or weight.